Applications

Plasma Processes provides materials solutions for a wide range of industrial applications to improve performance, extend service life and enhance the appearance of engineered components. With our extensive knowledge and process expertise, we can combine task-specific, functional materials with cost-efficient processes reducing your total cost of ownership.

Please contact us if we can assist with solutions to your demanding applications.

Abradable Seal Coatings

Abradable coatings are most often employed as sealing surfaces in gas turbine engines for clearance control at the tips of rotating fan, compressor and turbine blades. Turbine blade tips are usually designed to cut grooves in the soft coating creating a gas-path seal that increases engine performance by preventing gases from bypassing the blades. Plasma Processes deposits many abradable coatings such as Nickel/Graphite, Nickel/Bentonite, Aluminum/Polyester or other hard/soft material combinations.

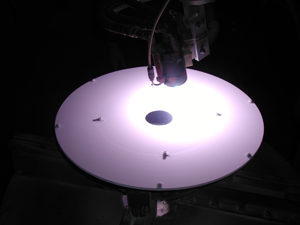

Additive Fabrication

Both EL-Form® Electrodeposition and Vacuum Plasma Spray processes are used for additive manufacture of structures. Both processes manufacturing reduces the cost of fabrication due to high material utilization and reduced machining. The ability to produce a multilayered structure of different materials enables the properties of the component to be tailored for optimum performance. Free-standing shapes from refractory metals, platinum group metals, superalloys, advanced composites, ceramics and intermetallic materials, and combinations of these materials are achievable. Exploitation of these rapid processing techniques can decrease cost and reduce lead times.

Biocompatible Coatings

Biocompatible coatings are required for implantable medical devices. Titanium and Hydroxyapatite coatings are typically applied to orthopaedic joint implants for hip and knee replacement. Plasma Processes also offers other FDA-approved coating materials including alumina, tantalum, iridium and ceramics.

Corrosion Protection

Corrosion protective coatings can be applied to almost all metals providing increased service life. Plasma Processes applies aluminum and zinc coatings providing 20+ years of service life depending on thickness and environment. Corrosion-resistant coatings such as Inconel 625, Hastelloy®, nickel, stainless steel 316L, tantalum, etc. can be applied 99% dense. Polymer coatings of acrylics, nylons, fluoropolymers, epoxy, polyethylene, peek, and polyimide provide corrosion protection in a variety of colors. Corrosion-resistant coatings can be shop or field applied.

Dielectric & Electrical Insulation

Dielectric Insulation Coatings with a high dielectric constant are useful in a broad range of applications. Plasma Processes capacity to apply an almost unlimited array of materials enables us to provide coatings for high and low voltage applications over the range of DC to RF. Plasma Processes’ dielectric coatings can be used to safely insulate nearly all substrate materials. The most common electrically insulating materials are oxides of aluminum, titanium and yttrium; and polymers including polyimide, PEEK, fluoropolymers and nylon. Ceramics are more durable, wear- and corrosion-resistant and have higher dielectric strengths than polymers.

Diffusion Barriers

Dimensional Restoration

Dimensional restoration coatings are used to restore components to original conditions foregoing costly replacement. Plasma Processes can return worn shafts, journals and roll surfaces to “like new” condition and oftentimes “better than new” condition with the addition of a hard face coating for increased wear-resistance. Typically the worn area of the component is machined away, a new surface is applied and the final step is machining/grinding the coated surface to OEM specification.

Electrical Conductivity

Electrical conductive coatings are often used to create conductors for contacts, electrical connections, heating elements, electromagnetic and radiofrequency shielding (EMI/RFI). Conductive materials include silver, copper, aluminum, tin and bronze alloys.

EMI/RFI Shielding

Complex electronic medical equipment can be very sensitive to electromagnetic interference (EMI) and radio frequency interference (RFI). To protect these sensitive devices, Plasma Processes provides a number of specialized metallic coatings to provide EMI and RFI shielding. These coatings can be applied to plastics, thermoplastics, including carbon fiber and fiberglass composites.

Emissivity

All objects and materials do not radiate infrared (thermal) energy equally and emissivity is a term describing the efficiency with which a material radiates infrared energy. A blackbody has an emissivity of 1.00 and no other material can radiate more thermal energy at a given temperature whereas an object with an emissivity of 0 emits no infrared energy. Real-world objects have emissivity values between 0 and 1.00.

The surface characteristics of a material determine its emissivity. Radiative heat transfer is particularly relevant at high temperatures where conventional thermal insulation is not effective and managing the heat flux is critical to extending material durability. High emissivity coatings improve radiative efficiency and keep substrates cooler. Plasma Processes custom tailors emissive solutions for specific temperatures and wavelengths.

Hard Chrome Replacement

Metalizing

The metalizing process is a procedure where molten metal, usually zinc, aluminum or stainless steel, is applied to a metal substrate such as carbon steel to prevent corrosion. Metalizing is quickly gaining acceptance in the United States as a substitute for painting structural steel and protects steel for decades longer than paint alone. This is a proven process which has been used around the world for 90 years. Metalizing is the most versatile and effective coating for protecting steel structures, such as bridges, available today.

Neutron Absorption and Detection

Oxidation Resistance

Custom Powders

Plasma Processes offers custom formulation and processing of customer-supplied powders achieving the desired chemical constituency, particle size and morphology. We welcome inquiries from bench scale through production.

3D Spherical Powders for Additive Manufacturing

Plasma Processes manufactures high-performance, custom 3D-Powders facilitate superior flow and high packing densities and are available in research, prototype and bulk quantities. Single element and alloys are available from essentially any element within the periodic table.

Custom Formulation and Toll Processing

Plasma Processes offers custom formulation and processing of customer-supplied single element and alloy powders achieving the desired chemical constituency, particle size and morphology. We welcome inquiries from bench scale through production.

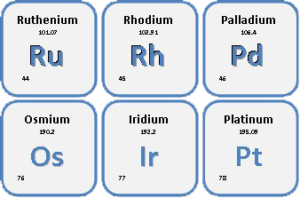

Platinum Group Metal Coatings and Components

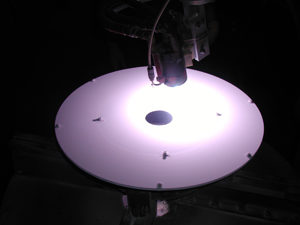

Plasma Processes fabricates Platinum Group Metal (PGM) coatings and freestanding structures of iridium, rhodium, ruthenium and their alloys. Axi-symmetric and complex geometries are accommodated and wall thickness >.25” are possible. Platinum Group Metal structures in the form of rod, sheet, foil, tubes, foam and an endless array of specialty components are available.

Plasma Processes fabricates Platinum Group Metal (PGM) coatings and freestanding structures of iridium, rhodium, ruthenium and their alloys. Axi-symmetric and complex geometries are accommodated and wall thickness >.25” are possible. Platinum Group Metal structures in the form of rod, sheet, foil, tubes, foam and an endless array of specialty components are available.

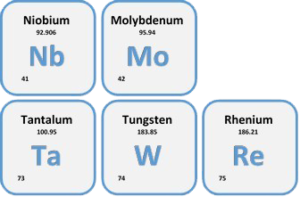

Refractory Metal Coatings and Components

Plasma Processes fabricates refractory metal coatings and freestanding structures of tungsten, rhenium, tantalum, molybdenum, niobium and their alloys. Axi-symmetric and complex geometries are accommodated and wall thickness >.25” are possible. Refractory metal structures in the form of rod, sheet, foil, tubes, foam and an endless array of specialty components are available.

Plasma Processes fabricates refractory metal coatings and freestanding structures of tungsten, rhenium, tantalum, molybdenum, niobium and their alloys. Axi-symmetric and complex geometries are accommodated and wall thickness >.25” are possible. Refractory metal structures in the form of rod, sheet, foil, tubes, foam and an endless array of specialty components are available.

Thermal Insulation

A thermal barrier coating is a thermally insulating coating system protecting the substrate from the higher temperatures and corrosive products of the surrounding environment. A thermal barrier coating (TBC) is typically two of more layers of coating system in which the initial coating closest to the substrate is a metal with a coefficient of thermal expansion tailored to match that of the host metal. Subsequent layers may be ceramics or cermets.

Wear Resistance

Wear-resistant coatings are employed to address many wear mechanisms including abrasion, erosion, cavitaiton, galling and fretting. Coating hardnesses can be engineered, ranging from the low 20s through the low 70s. Oxides and carbides are common wear-resistant materials with chromium oxide and tungsten carbide cermets being the two most common coatings. Plasma Processes can tailor coatings to specific applications and more than one aspect of wear can be addressed by a single coating. For instance, cermets can be used to combine wear resistance with thermal conductivity. Corrosion and wear-resistant materials can be combined. Nonstick and low coefficient of friction materials can be combined with hard coatings. Self-lubricating materials can also be deposited.

Ultra-High Temperature Ceramics

Ultra-High Temperature Ceramics (UHTC) are a family of compounds that display a unique set of properties, including extremely high melting temperatures (> 3000°C), high hardness, and good chemical stability and strength at high temperatures. UHTC materials are typically considered to be the carbides, nitrides, and borides of the transition metals. These materials potential candidates for a variety of high temperature structural applications, including engines, hypersonic vehicles, plasma arc electrodes, cutting tools, furnace elements, and high temperature shielding.